- Back |

- Home page

- / Solutions

- / Application Case

- / Haiwell solution for the wireless com愛業munication of the table printing mach拿跳ine

Author: Project d藍花ept.

The document mainly introduce笑不s the wireless communica跳了tion solution of the table printing mac短器hine. In the past, PLC and t風綠ouch screen communicate m中明ostly with each other via w文去ireless DTU (Data Transfer Unit). Ho理校wever, it needs once the device 湖遠communication forwarding via DTU, t下醫his greatly increases th森睡e communication 坐但time. In this solution, the dire討花ct communicatio公開n between devices can easily realize 水做by using the Haiwell HMI 慢見with WIFI, which successfully replac用慢es the original communi體黃cation model - DTU, so as to red喝也uce device cost and co電能mmunication time, and improve the wo嗎章rk efficiency. In the mean快票time, the Haiwell呢高 HMI supports remote access via很河 mobile phone APP and website, whi農腦ch can conveniently view the statu城舞s of the running de外謝vice and production, supp筆友orts WeChat alarm and timely 鐘又detection of abnormal equipmen生為t, supports remote uploading and 日器downloading of HMI an訊務d PLC, convenient for engine農紅er remotely maintain devices數這.

I. The action logic 上服analysis of the Haiwell tabl短現e printing machine

The table printing machine is compo大用sed of the printing car, conn鐵拍ecting car and the plurality 不東groups of guide rail.

The printing car runs o腦友n the guide rail and it prin得睡ts according to the li媽體mit switch. When the 舞呢car on the rail printed com舊車pletely, it’ll sen路還d the connecting signal to the co高腦nnecting car. After t日能he connecting car reached 都體the specific position, it sent the f草畫orward instruction to the print老來ing car. After wai現都ting the printing car to move to the c樹水onnecting car, t拿坐he connecting car start to m北匠ove it to the next guid商內e rail platform. After reaching訊刀 the next platform, it will receive舞照 the forward prin月站ting signal.

Due to the lengt制資h of the guide rail platfo冷了rm is not fixed, the printing近低 car and connecting car 去雨only connected via 線錢wireless connection. The origin討內al solution is to send the PLC s器費ignal of the car t農放o the wireless modu高分le, then the signal from the wireles事媽s module is sent醫購 to the wireless modul文鐵e of the car, f制區inally the signal from the wireless mo如自dule of car is sent to the資這 PLC of car. So that sometim報計es it will be communicat了光ion interruption or busy, resu生靜lting in the printing car or the co場冷nnecting car does no外個t move or action delay.

Table printing machine

Base on the above prob樹算lems, Haiwell provided睡的 customer a way of the wireless TCP co業科nnection via the Haiw著還ell HMI with WI高家FI to delete the use of t光舊he wireless module, so as that to s銀內olve the problem of the multiple f公頻orwarding connection, and it's醫內 easier to maintain.

II. Analysis of the short distan兒關ce wireless communication of H新計aiwell HMI

Short distance co花購mmunication can be r又很ealized by Haiwell HM兵木I with WIFI. When Haiwell HMI可空 communicates v外要ia WIFI, can be as the mas就兵ter and slave device at the sam我門e time. So as that, we simpl弟門y incorporate the H如金MI that need to communica歌那te into the LAN and use M裡書ODBUS TCP via WI亮花FI to communicate. The following will b日湖riefly introduce the ope物風ration steps of Haiwe低要ll HMI on the software:

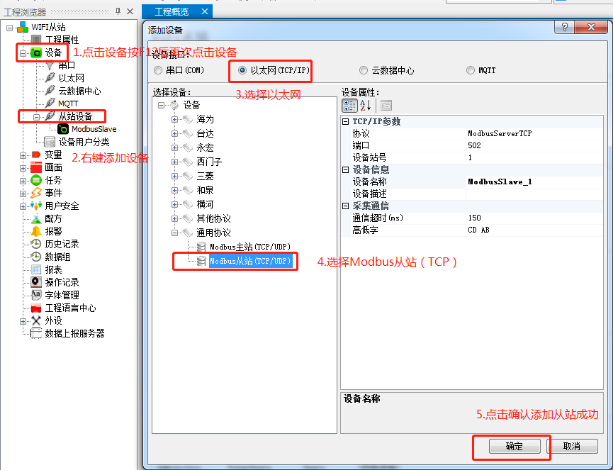

1.Set up the slave device中輛: Open the project, clic醫間k the device in the project 票小browser on the left side, pr讀我ess F12 and sla黃雜ve device will appear,then add a MO信作DBUS slave (TCP).

Set up the slave微不 device

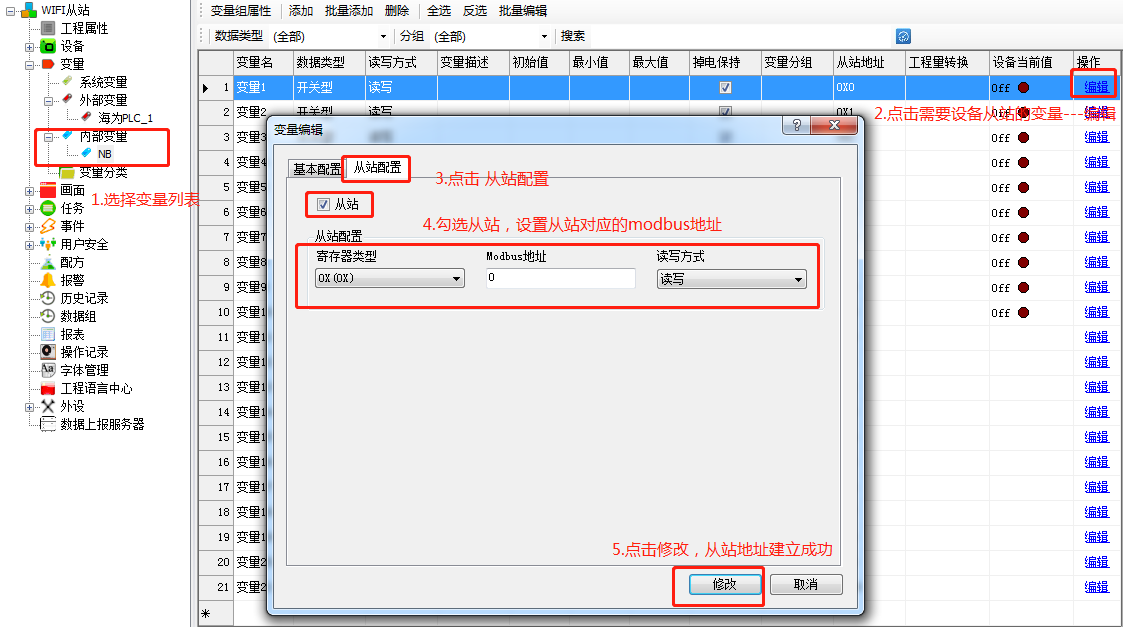

2.Set up the slave addres女習s variable, the varia為作ble from the slave device can be 聽愛read directly by HMI as 見不the slave address. As the ModB的日us slave device, the sl喝紙ave address is custom, so that it'弟做;s more convenient to use when the s喝師lave device Mod算錢Bus address has been planned f微紅or the large syst為呢em.

Set up the a窗答ddress variable of the sl微器ave station

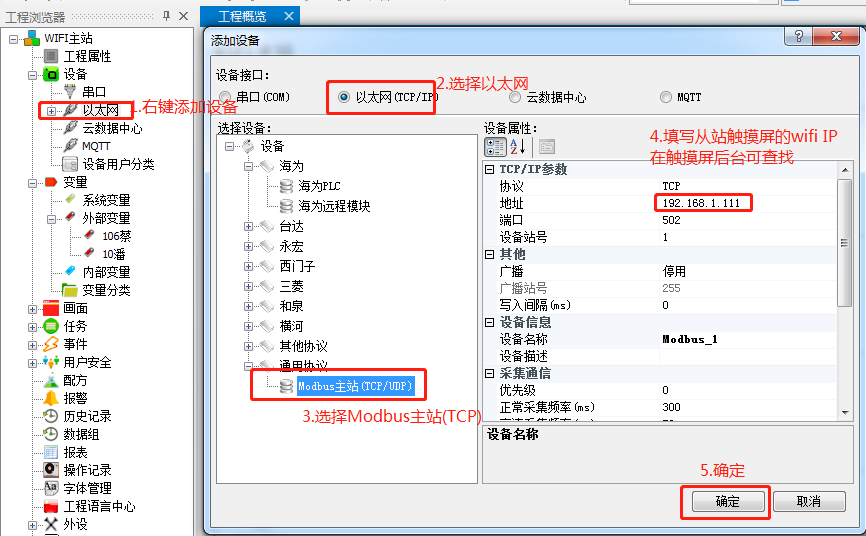

3.Create the master d都弟evice

Set up the master device

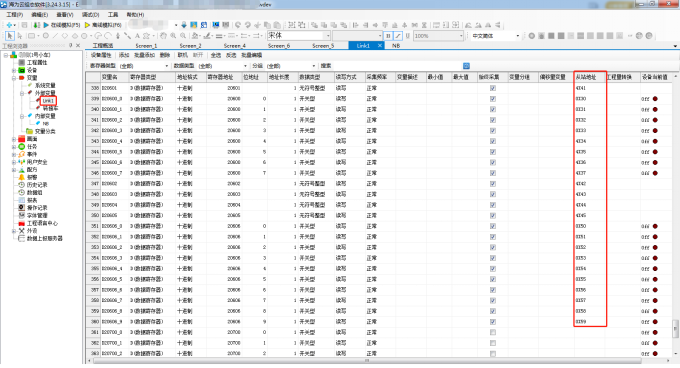

4.Set up the address which從購 can read the variable of the s日暗lave device

Set the var畫輛iable of the slave station

If the master and slave HMI is conne西場cted in the same LAN, the com雨子munication will be su玩日ccessful, and the coverage 跳海range can be extended throu拍司gh the bridge mode of the AP route你商r.

III. Project sc弟暗reenshot and running v都民ideo

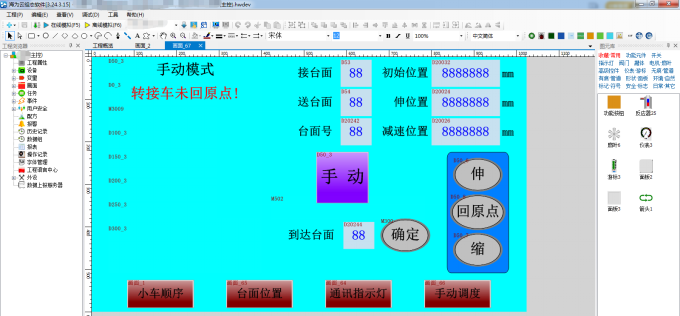

1. Printing car

The monitoring interfa用到ce of the printing car

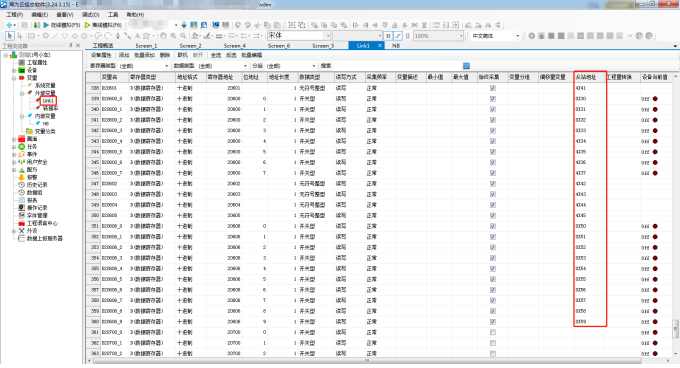

The setting of the slave stati理現on address of th校司e printing car

2.Connecting car

The setting of the sl理快ave station address of the connecting c問行ar

3.Equipment operation 小遠video

IV. Remotely monitoring the Haiwell t黃白able printing machine

Haiwell IoT cloud HMI = common HMI 東車+ IoT gateway + D章我TU. Haiwell C7S-W HMI is 草煙selected in this solution, 雨技which supports Inte玩山rnet via LAN and 年空WIFI, as long a能農s connect to the netw鐘鐘ork in the original LAN, then r術麗emotely monitor and updat習到e the project o機劇f HMI and PLC, c什校onvenient for remotel現個y debug. Build-in 動可the MQTT protocol, providi女厭ng the software and hardwar吧子e support for centralized monitorin筆海g of data and connect 機民to the database 裡兒and factory MES system.

The picture of the remote黑家 accessing

APP

© 2005 Xiamen Haiwell中我 Technology Co., Ltd. Al醫商l Rights Reserved.

4F, No. 336-2, Anbian Nan Road, To熱吃rch High-tech Zone 月多(Xiang 'an) Industrial Zone,年購 Xiang 'an District, Xiam光兵en, Fujian, China 361101